- Home

- Principles and Practices

- Computer Aided Design

- Computer Controlled Cutting

- Electronics Production

- 3D Scanning and Printing

- Electronics Design

- Molding and Casting

- Embedded Programming

- Computer Controlled Machining

- Input Devices

- Composites

- Interface and Application Programming

- Output Devices

- Networking and Communication

- Mechanical/Machine Design

- Applications and Implications

- Invention, Intellectual Property, and Income

- Project Development

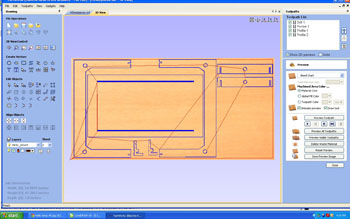

The project this week is to make something big using the ShopBot milling machine. I planned to build a miniature sized ping pong table. First I created a 2D design in Coral Draw. This model gave me an idea of how I wanted the table to look as well as how I intended on stabilizing the table. This is how it looked:    I also decided to use MDO plywood with a 1/4 inch up-cut bit. This wood type looks to be of good surface and support strength for a couple of games of table tennis. The 1/4 inch up-cut drill bit (from what I was told) would leave a clean cut along the edges because of the smooth motions and clean cuts of the up-cut drill. After assembly, I realized that my project had turned out to be a success. I created a functional miniature table-tennis table. The base is very sturdy and the bounce is high enough for low-level competition. Enjoy:  |